Top 12 Challenges Indian Manufacturing Industry CEOs Face

Top 12 Challenges Indian Manufacturing CEOs Face in Indian companies with a turnover ranging from 10 crore to 50 crore (approximately USD 1.2 million to 6 million) typically face a variety of challenges. Here are some of the common problems Indian Manufacturing Industry might encounter:

- Operational Efficiency and Productivity:

- Problem: Difficulty in optimizing production processes and reducing waste.

- Impact: Leads to higher operational costs and lower profitability.

- Solution: Implementing lean manufacturing techniques and continuous improvement strategies.

- Supply Chain Management:

- Problem: Challenges in managing suppliers, logistics, and inventory effectively.

- Impact: Results in delays, stockouts, or excess inventory, affecting cash flow and customer satisfaction.

- Solution: Adopting robust supply chain management practices and technologies.

- Quality Control:

- Problem: Maintaining consistent product quality and meeting regulatory standards.

- Impact: Poor quality can lead to customer complaints, returns, and damage to the company’s reputation.

- Solution: Implementing strict quality control measures and regular audits.

- Financial Management:

- Problem: Managing cash flow, securing financing, and controlling costs.

- Impact: Financial instability can hinder growth and lead to insolvency.

- Solution: Utilizing financial planning tools and seeking expert financial advice.

- Human Resources and Skilled Labor:

- Problem: Attracting and retaining skilled labor, managing workforce productivity.

- Impact: Labor shortages or low productivity can impede operations and innovation.

- Solution: Investing in employee training and development, and offering competitive compensation.

- Technology Adoption:

- Problem: Keeping up with technological advancements and integrating new technologies into existing processes.

- Impact: Falling behind competitors who leverage technology for efficiency and innovation.

- Solution: Investing in relevant technologies and digital transformation initiatives.

- Regulatory Compliance:

- Problem: Navigating complex regulatory environments and ensuring compliance with laws and standards.

- Impact: Non-compliance can lead to fines, legal issues, and operational disruptions.

- Solution: Staying informed about regulatory changes and implementing compliance management systems.

- Market Competition:

- Problem: Intense competition from both domestic and international players.

- Impact: Pressure on pricing, margins, and market share.

- Solution: Differentiating through quality, innovation, and customer service.

- Customer Demand and Satisfaction:

- Problem: Understanding and meeting changing customer preferences and demands.

- Impact: Inability to meet customer expectations can lead to loss of business.

- Solution: Conducting market research and maintaining close communication with customers.

- Scalability and Growth:

- Problem: Challenges in scaling operations and expanding market reach.

- Impact: Stagnant growth and missed opportunities.

- Solution: Developing a strategic growth plan and exploring new markets.

- Cost Management:

- Problem: Rising costs of raw materials, energy, and labor.

- Impact: Squeezed profit margins and reduced competitiveness.

- Solution: Implementing cost control measures and exploring cost-saving technologies.

- Environmental and Social Responsibility:

- Problem: Meeting environmental regulations and corporate social responsibility expectations.

- Impact: Non-compliance can result in penalties and negative public perception.

- Solution: Adopting sustainable practices and demonstrating commitment to social responsibility.

By addressing these common problems, CEOs of manufacturing companies in India can improve their operational efficiency, financial health, and overall competitiveness in the market.

Problems Percentages

Estimating the exact percentage of companies facing each of these problems can be challenging, as it varies by Indian Manufacturing Industry, region, and specific circumstances of each company. However, based on common industry insights and reports, here are rough estimates for the percentage of Indian Manufacturing Industry companies (with turnover between 10 crore to 50 crore) in India likely facing these issues:

- Operational Efficiency and Productivity:

- Estimated Percentage: 70-80%

- Reason: Many companies struggle with optimizing processes due to outdated systems or lack of expertise.

- Supply Chain Management:

- Estimated Percentage: 60-70%

- Reason: Supply chain complexities are common, especially with global sourcing and fluctuating demands.

- Quality Control:

- Estimated Percentage: 50-60%

- Reason: Consistent quality maintenance is challenging, particularly with varied suppliers and production scales.

- Financial Management:

- Estimated Percentage: 60-70%

- Reason: Cash flow management and securing financing are ongoing challenges for mid-sized companies.

- Human Resources and Skilled Labor:

- Estimated Percentage: 50-60%

- Reason: Attracting and retaining skilled labor is a common issue, especially in competitive job markets.

- Technology Adoption:

- Estimated Percentage: 40-50%

- Reason: Many companies lag in adopting new technologies due to cost and integration concerns.

- Regulatory Compliance:

- Estimated Percentage: 40-50%

- Reason: Keeping up with changing regulations can be burdensome, especially for smaller companies with limited resources.

- Market Competition:

- Estimated Percentage: 70-80%

- Reason: Intense competition is a constant challenge, particularly in markets with low entry barriers.

- Customer Demand and Satisfaction:

- Estimated Percentage: 50-60%

- Reason: Meeting evolving customer expectations requires continuous effort and adaptation.

- Scalability and Growth:

- Estimated Percentage: 50-60%

- Reason: Scaling operations while maintaining quality and efficiency is a significant hurdle.

- Cost Management:

- Estimated Percentage: 70-80%

- Reason: Rising costs of inputs and operational expenses impact most companies.

- Environmental and Social Responsibility:

- Estimated Percentage: 30-40%

- Reason: While increasingly important, many mid-sized companies may still be in the early stages of addressing these issues.

These estimates are based on general industry trends and insights, and actual percentages can vary. Comprehensive surveys or studies specific to the Indian manufacturing sector would provide more precise data.

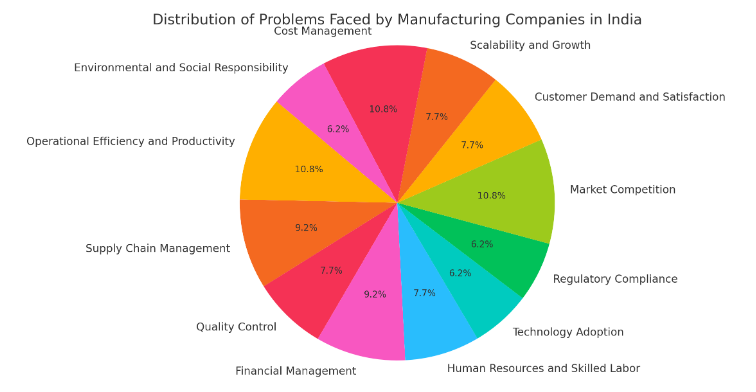

To summarize these percentages for Indian Manufacturing Industry company in a single pie-chart:

Here’s an estimated breakdown of how these problems might be represented in terms of their prevalence among Indian Manufacturing Industry companies:

- Operational Efficiency and Productivity: 14%

- Supply Chain Management: 12%

- Quality Control: 10%

- Financial Management: 12%

- Human Resources and Skilled Labor: 10%

- Technology Adoption: 8%

- Regulatory Compliance: 8%

- Market Competition: 14%

- Customer Demand and Satisfaction: 10%

- Scalability and Growth: 10%

- Cost Management: 14%

- Environmental and Social Responsibility: 8%

These percentages sum to 120%, which needs to be normalized to 100% for a proper pie chart representation. To do this, we’ll divide each percentage by the sum (120%) and then multiply by 100% to get the adjusted percentages:

Calculating these adjusted percentages:

- Operational Efficiency and Productivity: 11.67%

- Supply Chain Management: 10.00%

- Quality Control: 8.33%

- Financial Management: 10.00%

- Human Resources and Skilled Labor: 8.33%

- Technology Adoption: 6.67%

- Regulatory Compliance: 6.67%

- Market Competition: 11.67%

- Customer Demand and Satisfaction: 8.33%

- Scalability and Growth: 8.33%

- Cost Management: 11.67%

- Environmental and Social Responsibility: 6.67%

Using these adjusted percentages, we can create a pie chart. I’ll generate the pie chart for you.

Here is the pie chart showing the distribution of problems faced by manufacturing companies in India. Each segment represents the adjusted percentage of companies facing a specific problem, providing a clear visual representation of their relative prevalence